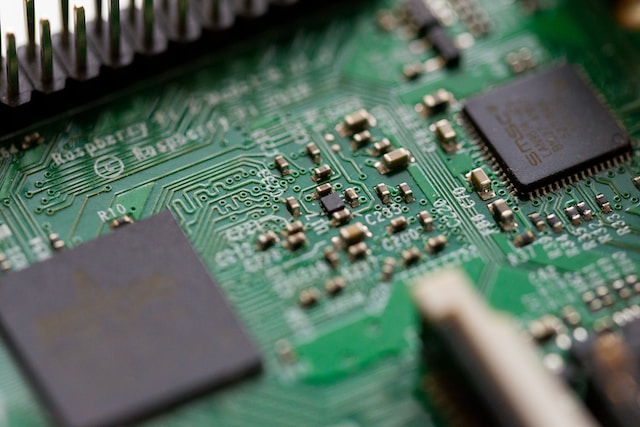

In the fast-paced world of semiconductor manufacturing, companies are constantly pushing the boundaries of what’s possible. One such company, Applied Materials, is making waves with its latest technology aimed at boosting chip factory productivity. With a commitment to innovation and a track record of success, Applied Materials is revolutionizing the semiconductor industry like never before.

Applied Materials has long been recognized as a pioneer in developing advanced solutions for chip fabrication. Its cutting-edge technology and manufacturing equipment have played a crucial role in enabling the production of smaller, faster, and more power-efficient chips. Now, with its latest breakthrough, the company aims to take chip factory productivity to new heights.

The new technology developed by Applied Materials focuses on streamlining the chip manufacturing process, optimizing efficiency, and reducing costs. By addressing key challenges faced by chip manufacturers, Applied Materials aims to revolutionize the industry and provide significant benefits for both manufacturers and end-users alike.

One of the key areas of focus for Applied Materials is improving yield and reducing defects in the chip fabrication process. Defects in semiconductor manufacturing can lead to reduced performance, increased costs, and wasted resources. To combat this, Applied Materials has developed advanced inspection and metrology solutions that allow manufacturers to detect and address defects at an early stage. By catching and resolving issues early on, manufacturers can significantly increase yield and improve overall chip quality.

Another critical aspect of chip factory productivity is equipment performance and maintenance. Applied Materials understands the importance of maximizing uptime and minimizing downtime in a highly competitive industry. To address this, the company has developed state-of-the-art predictive maintenance solutions that leverage artificial intelligence and machine learning. These technologies enable real-time monitoring and analysis of equipment performance, allowing for proactive maintenance and minimizing the risk of unexpected breakdowns. As a result, chip manufacturers can optimize equipment utilization and reduce costly downtime.

Furthermore, Applied Materials’ new technology offers enhanced process control capabilities, enabling tighter control over critical manufacturing parameters. This level of precision helps ensure consistent chip performance and reliability across production batches. By leveraging advanced process control techniques, manufacturers can achieve higher yields, reduce waste, and improve overall product quality.

Applied Materials’ commitment to sustainability is also evident in its new technology. The company’s solutions focus on energy efficiency, waste reduction, and environmentally friendly practices. By optimizing the manufacturing process, reducing resource consumption, and minimizing waste, Applied Materials is helping chip manufacturers align with sustainability goals while remaining competitive in the market.

In conclusion, Applied Materials is revolutionizing chip factory productivity with its groundbreaking technology. By addressing key challenges faced by the semiconductor industry, Applied Materials’ innovative solutions are driving increased efficiency, reduced costs, and improved overall performance. With its commitment to continuous innovation, the company is shaping the future of semiconductor manufacturing, setting new standards, and empowering manufacturers to stay ahead in the rapidly evolving world of technology.