This collaboration promises to improve efficiency, reduce costs, and streamline production processes for high-quality tooling solutions.

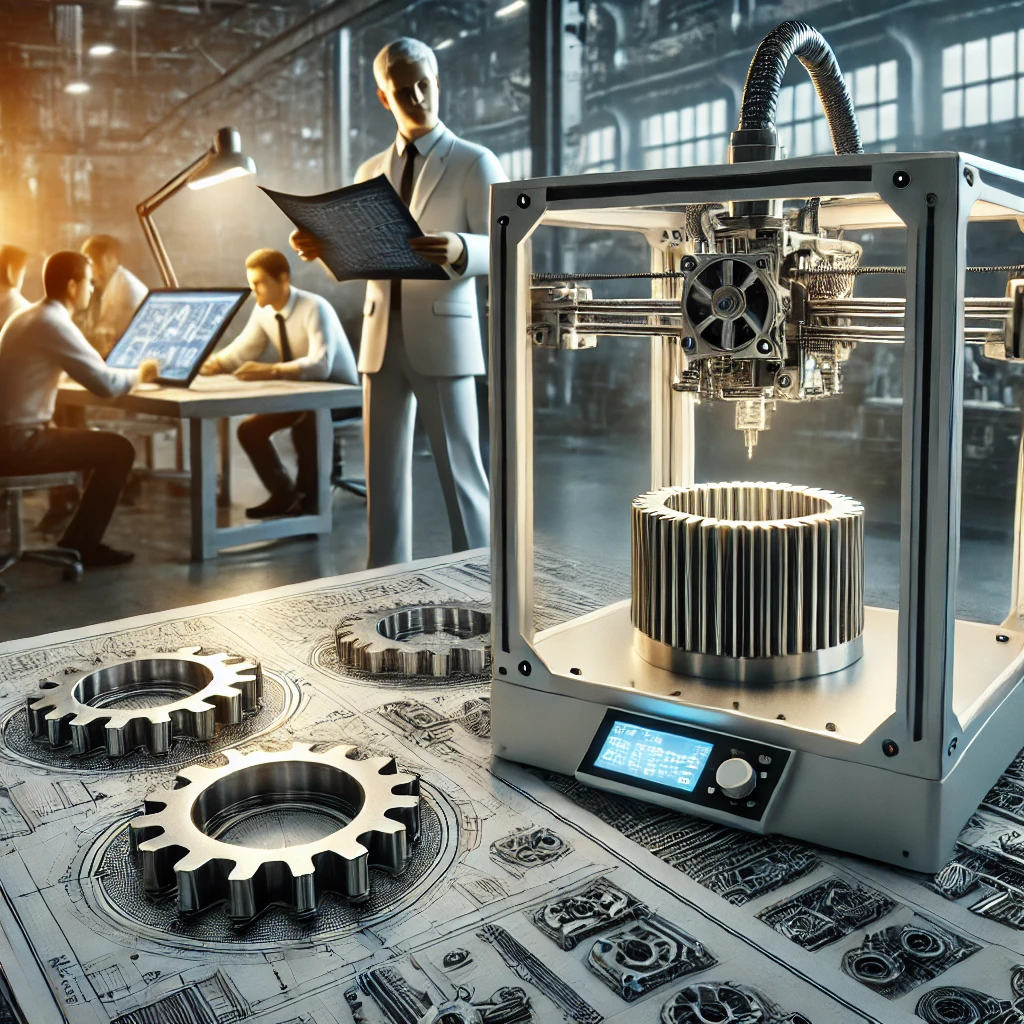

What is 3D Printed Tooling?

. This leads to less material waste, reduced production time, and enhanced customization.

Airtech and Ascent Aerospace Partnership

The partnership between Airtech and Ascent Aerospace is a game-changer for the aerospace and defense industries.

Why 3D Printed Tooling for Aerospace and Defense?

Aerospace and defense sectors require precision, high-performance, and lightweight materials, all of which can be achieved with 3D printed tooling.

Cost Efficiency

3D printing reduces material waste, cutting down on expenses.

- Faster Production: It allows for quicker prototyping and tooling creation, reducing lead times.

- Customization: Manufacturers can create highly customized and complex designs that are often impossible with traditional methods.

To learn more about the benefits of 3D printing in aerospace, read this article on aerospace 3D printing innovations.

How Does the Partnership Benefit Aerospace and Defense?

- Increased Efficiency: With faster lead times and reduced production costs, companies can produce complex parts more efficiently.

Benefits of 3D Printed Tooling

- Speeds Up Time to Market: Faster production and prototyping mean that companies can bring their products to market more quickly.